- |

- Inquiry List

- |

- Sign In or Sign Up

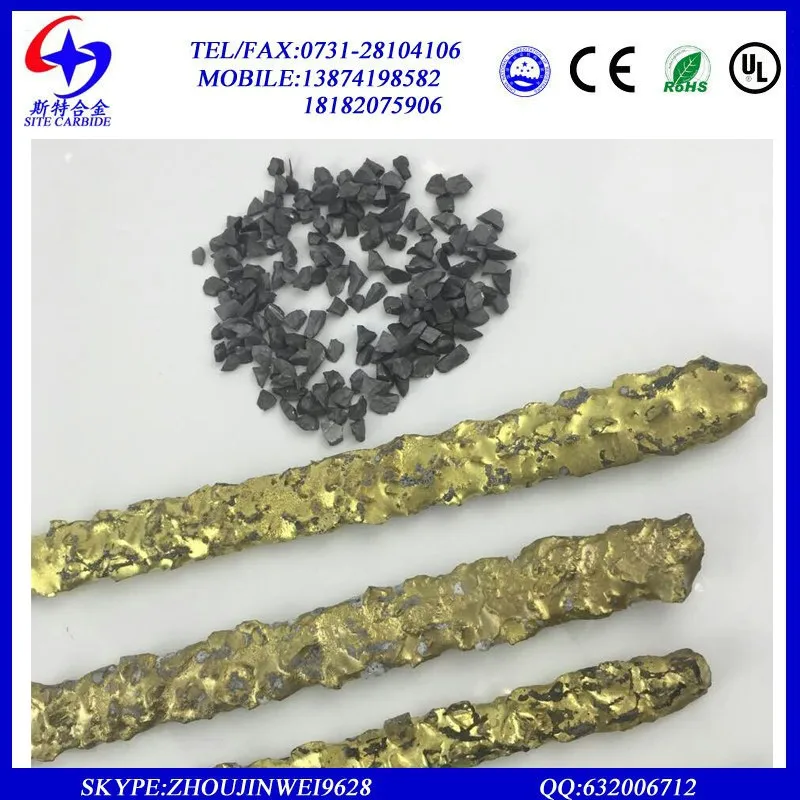

Tungsten carbide scraps/ Carbide broken grain

Tungsten Carbide Grit is the material applied to components of applications with a high level of abrasion. It is applied as an overlay through a process called hardfacing. Hardfacing is a process in metalworking where tougher and harder material is applied to a base metal. Tungsten carbide grit is used above most traditional hardfacing materials because it is harder and is proven to be a more effective protection against wear from abrasion.

Tungsten Carbide Grit can be created to suit individual applications and work environments. One can alter the grit mesh size as well as the wire matrix to achieve the desired balance of protection from abrasion and impact.

Through hardfacing, tungsten carbide grit can be applied to a new part in order to better its wear resistance or to a used part to restore its worn-down surface.

Grit is used for long lasting wear protection in areas of high abrasive wear. It is used to keep costly parts – bulldozer blades, wood grinding tips, trencher teeth, and bucket teeth – from wearing down quickly. Using tungsten carbide grit on machinery parts that see a lot of wear and tear significantly extends the life of those parts. For this reason it is used in many different applications including woodwaste, agriculture, wear parts, plow attachments, and drilling. Grit adds an extra layer of protection to costly parts, increasing efficiency and decreasing downtime.

Tung Grit products containing rounded carbide particles offering superior wear protection, under conditions of low to moderate impact, through a combination of the inherent hardness of the Tungsten Carbide, and the “dead box” effect arise when particles of the abrasive material in contact with the hard facing are trapped between the carbide particles. This build-up causes “material on material” bulk flow, the base material thus being protected from abrasion damage..

Tung Grit is also supplied with sharp/blocky tungsten carbide grit for “cutting” applications where the excellent hardness of the tungsten carbide provides superior cutting performance.

Carbide broken grain is kinds of particles of hard alloy by cemented carbides broken method.

Carbide broken grain's particle size is 1mm~10mm different size.

Can be customized different size product for customer requirement.

1. Description of tungsten carbide grit

This tungsten carbide grit also called tungsten grints, carbide grits, it is used to welding or solder onto a steel body, to increase the wear resistance properties. For example, if a steel cutter can cut 24 hours without grits, it will cut 240 hours after with the tungsten carbide grits.

2. The physical properites of tungsten carbide grit

|

Cobalt % |

WC % |

Hardness (HRA) |

Density (g/cm3) |

TRS (MPA) |

|

7-8% |

92%-93% |

89.5-90.5 |

14.6-14.85 |

> 2500 |

3.The strength of tungsten carbide grit

High hardness and wear resistance

Easily be brazed

Virgin material, good properties

All grain size (mesh) are avaiable

4. Range of tungsten carbide grit

The normal size (mesh) of tungsten carbide grits

5-8mesh ,

14-25 mesh,

20-30mesh ,

30-40mesh,

40-60mesh,

50-60mesh,

60-80mesh .

Products show